Greener Calcite Industry: 105MW PV Plant in Turkey

Capacity:

105 MW

Annual Output:

1.8 GWh

COD Time:

2023. 11

The Background

Calcite production is a major industry in Turkey, but traditional mining and processing techniques can have a significant impact on the environment, especially in terms of energy consumption. To address this, Mikrokal, one of the country's top calcite producers, launched a 105 MWAC solar PV project in Niğde. Developed with Niğtaş and supported by Sungrow, it is designed to power Mikrokal's mining and processing facilities while reducing reliance on fossil fuels.

The Challenges

Calcite production is a highly energy-intensive process, requiring consistent, scalable, high-output power. The project also had to contend with the region’s mountainous terrain, which made it difficult to design a layout that could maximize solar yield.

The Solution

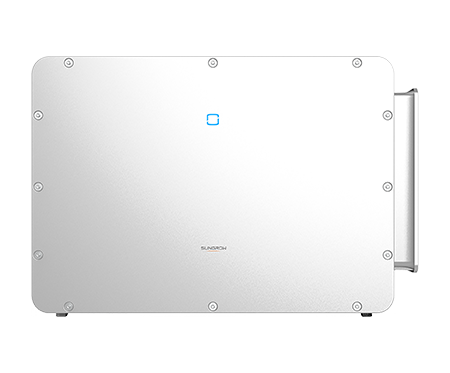

With the help of Sungrow, Mikrokal devised a system that involved the installation of 95 units of Sungrow’s SG1100UD modular inverters, each delivering 1.1 MW. Paired with bifacial modules on single-axis trackers and mounted on white gravel, the system marked the country’s first deployment of the 1+X modular inverter solution. Sungrow also provided on-site training, enabling the client’s team to ensure reliable, long-term operation.

The Impacts

This project is a milestone in Turkey’s clean energy journey, allowing one of the country's main high-tech industries to be powered by solar. It's a testament to how Sungrow’s solutions can be scaled globally. For Mikrokal and the community, it showed that the renewable energy movement and industrial growth do not need to be mutually exclusive.

ABOUT MIKROKAL

Founded as a private company in 1986, Mikrokal expanded its operations in 1996 under the name ‘Niğtaş Ltd. Şti.’ Mikrokal’s micronized calcite (natural calcium carbonate) processing began in 2004 to increase its market share with the advantage of its high raw material quality and capacity. Mikrokal has been serving various sectors such as paint, plastics, paper, and construction chemicals with its logistics facilities, with nanometric calcite and hydrophobic nanometric calcite production in 2010, its surface coating plant in 2011, and its increased granule capacity in 2012.