SGCX in Parallel with SHT Series: Warehouse C&I ESS Project in Italy

Project name:

SEP ENERGIA S.R.L

Installed Capacity (PV):

68.2 kWp

Inverter:

SG50CX SH15T

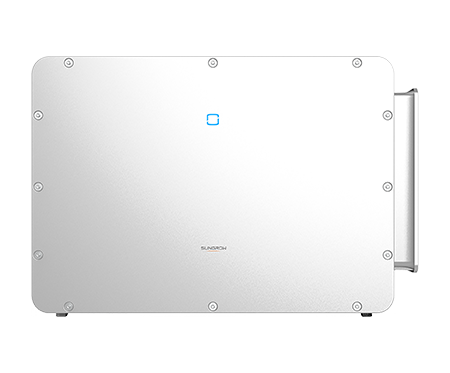

Battery:

SBH100

The Background

In Parma, Italy, a cutting-edge project has seamlessly integrated Logger control with SHT and SGCX models to power a warehouse, offices, and electric vehicles. Built upon an SG50CX foundation, the system now parallels four Sungrow SH15T units, significantly enhancing solar energy efficiency. Excess daytime electricity is stored in batteries, ensuring a continuous energy supply during nighttime and early morning hours. This milestone project, connected to the grid on August 30, 2024, is Europe's first successful test plant for Logger control of SHT+CX models, setting a new standard for sustainable energy integration. As distributed energy resources expand, the role of such integrated plants in ensuring grid stability becomes increasingly crucial. In Italy, it is particularly noteworthy that Sungrow's SHT series products have attained both CEI0-16 and CEI0-21 system certifications. This project is a prime example of Sungrow's commitment to promoting sustainable energy in the small-scale commercial and industrial sectors.

The Challenges

The primary challenge was a warehouse requiring a 24/7 energy supply, particularly for its power-intensive refrigeration units. The existing AC-coupled system was insufficient to meet these demands. Furthermore, spatial constraints presented a hurdle for conventional containerized Energy Storage System (ESS) solutions—a common issue in small-scale C&I environments. On a positive note, the warehouse also featured ample roof space, presenting an ideal opportunity to install solar panels and meet the facility's daytime energy needs.

The Solution

By integrating Sungrow’s PV and storage systems, businesses can fully utilize their rooftop space, turning every square meter into an energy asset. The SG50CX inverter boosts daytime self-consumption beyond AC-coupled limits, while the SHT and SBH storage solutions capture and store excess power for later use. The system is also scalable, ready for future expansion of its PV, inverter, and battery capacity. Designed for tight spaces, the modular and stackable SBH solution fits easily into compact warehouses without needing cranes or forklifts. In facilities like the Parma power station, its simple installation and the SG50CX’s superior heat dissipation keep performance high where space is at a premium. For small businesses, Sungrow offers true energy independence. The system supports up to 13 units in parallel, unlocking greater profits from surplus solar. Retrofitting and expansion are also effortless; thanks to the Logger, new PV, storage, or AC-coupled units can be added without disrupting operations. And when the unexpected happens, Sungrow keeps the lights on. The system delivers reliable backup power for offices, warehouses, and refrigeration units, allowing equipment and businesses to run 24/7.