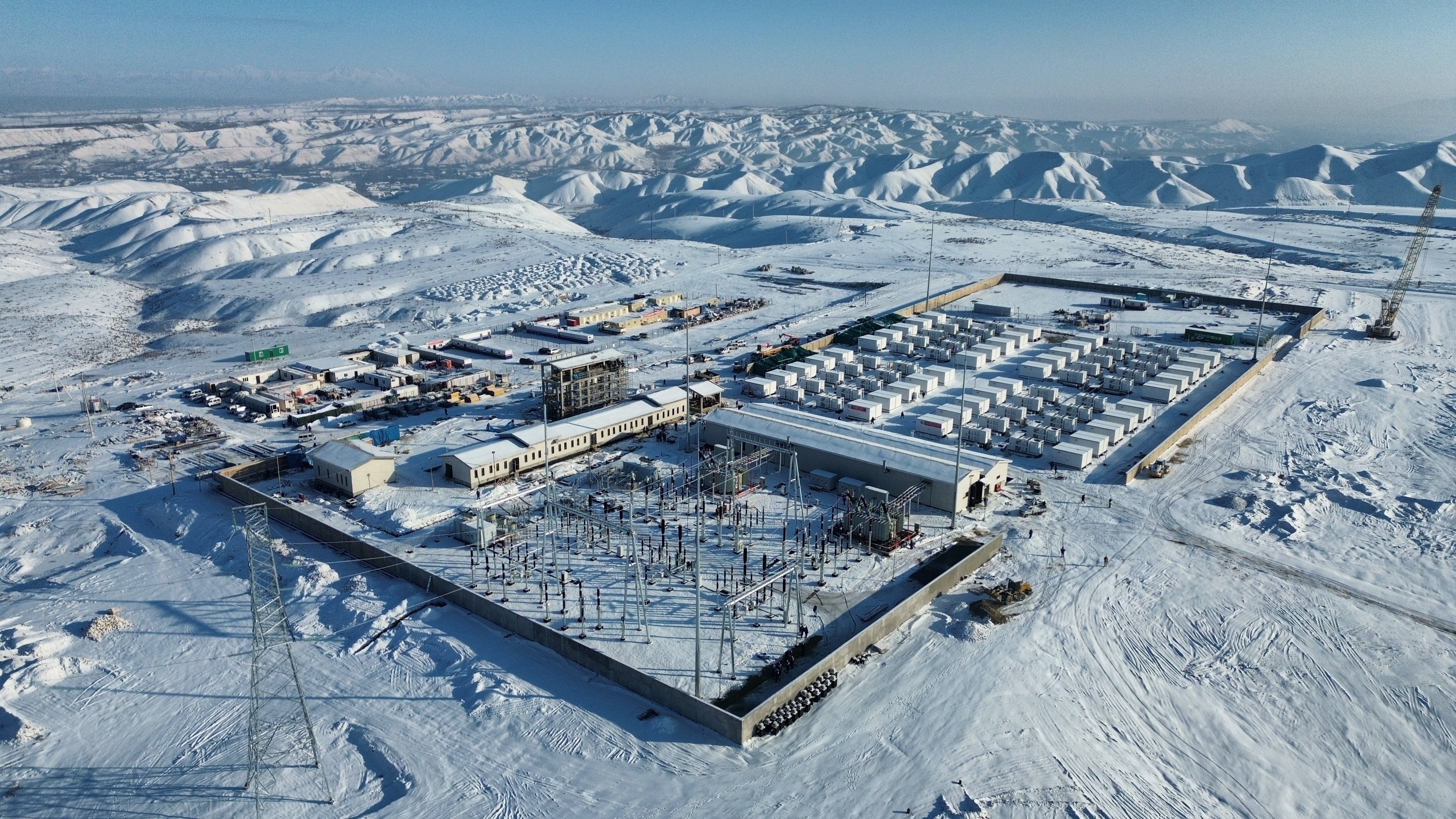

Against the Desert Storms Lochi, Uzbekistan: 150 MW/300 MWh Energy Storage Project

Capacity:

150 MW/300 MWh

COD Time:

2025

Inspired by Legends of the Past - The ‘Sungrow Model' Standard

Along the Silk Road, the legendary Ferghana horses once bridged trade routes between the East and the West. Today, that spirit of drive and resilience lives on in the newly connected 150 MW/300 MWh energy storage project in Andijan, Uzbekistan. Led by the Sungrow team, the project overcame complex technical barriers to achieve seamless integration with the local power system. As one of the largest energy storage deployments in Central Asia, it marks a breakthrough for Chinese energy enterprises in the region and sets a new standard for future-ready grid infrastructure. The “Sungrow Model” is fast becoming a global reference for next-generation power systems. At the start of the project, the Sungrow team worked closely with clients to ease their concerns about the technology and investment risks. Through clear explanations, tailored solutions, and hands-on support, the team gained its clients’ confidence and helped fast-track decisions.

Building Trust That Reaches Across Borders

Trust was built step-by-step—by organizing factory tours for Uzbek officials, demonstrating product performance with clients, and showcasing real-world results through immersive exhibitions. When faced with certification gaps and competitor skepticism, the team shared detailed cost comparisons and case studies, showing how PowerTitan 2.0 could reduce space requirements by 50% and boost energy efficiency by 40%. The result is Sungrow’s first PowerTitan 2.0 project abroad.

Adapting to Solve Logistics Challenges

Transporting large-scale equipment to Uzbekistan was no easy task, with challenges including strict customs laws, limited vehicle availability, and unexpected policy changes. However, with smart planning, real-time coordination, and a flexible, problem-solving mindset, the Sungrow team overcame each hurdle. Every step of the delivery process—from factory to site—was closely monitored to ensure the safe and prompt arrival of all required equipment.

A Tight Schedule A Tighter Team On-Site and Off

With tight deadlines and no room for error, the Sungrow team on the ground pushed hard through the final stages of the project. Crews worked around the clock, provided daily progress reviews, and received real-time guidance from remote experts. Even when severe weather cut off communication, on-site teams found ways to stay on track—manually logging data and driving it out for reporting. When equipment issues arose, they responded immediately, making repairs under extreme heat to avoid delays. Thanks to this collaborative spirit, the project was commissioned ahead of schedule and achieved a smooth first-time connection to the grid.

One Step Closer to the Clean Energy Revolution

The successful delivery of the project reflects the team’s solid capabilities in innovation, coordination, and execution under challenging conditions. It offers a meaningful reference point for similar renewable energy projects in Silk Road markets. By working closely with partners and addressing concerns through practical solutions, the team helped build confidence and move the project forward. This achievement represents a thoughtful contribution to the ongoing global shift toward cleaner, more reliable energy.